What We Do

We specialized in manufacturing metal, plastic hardware (parts) components, including CNC turning, CNC milling, multiple axis CNC machining, and die casting, also offer one stop service for mold building, injection molding, sheet metal fabrication, surface finishing.

CNC Milling

CNC turning process is to make CNC milled parts, a block or sheet is clamped on a working table, and a spindle which holds the cutting tools. A computer controls the tool used, the rotation speed and the vertical motion of the spindle, and the horizontal motion of the table. It allows loading cutters such as drills, taps and end mills to remove portions of the material to create designed shapes.

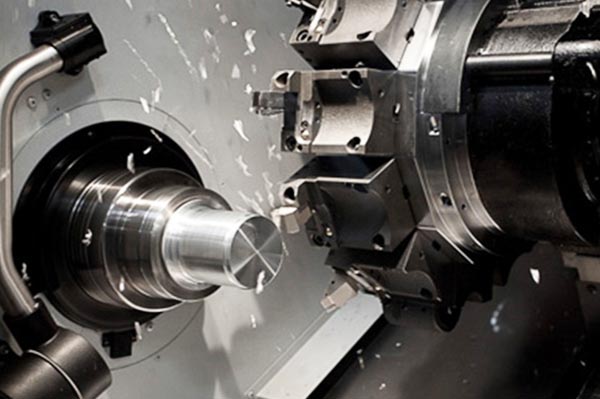

CNC turning

CNC turning is a manufacturing process for getting desired shape parts with bars of material held in a chuck and rotated while a tool is fed to the piece to remove material, normally the sections of machined areas on every place of CNC turned parts along its axial direction is round, or some other symmetrical shapes.

Multi-Axis CNC machining

Multiple axis CNC machining is a manufacturing process where tools can move in 4 or more ways/direction to manufacture parts which require precision machining, delivering innovative and efficient solutions for complex geometry parts. Multi-axis CNC machines can deliver the close tolerance components and offer greater flexibility and cutting-edge machining technology as it can process five sides of a part in a single setup.

Die Casting

Die casting is a manufacturing process for complex-shaped aluminum alloy, zinc alloy or magnesium-aluminum alloy components / parts, during die casting the molten metal goes into cavities under high pressure. The mould cavity is created by two hardened tool steel dies which have been machined into shape and work similarly to an injection mould during the process. It has features of high production of efficiency and low costs.

One-stop Service

Other machining processes including plastic injection molding, tooling building, surface finishing, heat treatment ad etc. Options for surface finishing are anodizing, sand blasting, electroplating, painting, polishing, knurling and etc. Heat treatment is for parts have hardness requirement to achieve high abrasive resistance, or impact resistant / toughness ability, others are for parts which required good surface /appearance.